Featured Article

Please see our Environmental Chambers / Environmental Test Chambers section to find manufacturers that sell these products

Did you ever wonder just how would your dependable lab equipment—or your smartphone, for that matter— function in, say, Antarctica? Or even just blocks from your home or lab? How long would your smartphone or tablet last if it were accidentally left outside, braving the elements for days at a time? Even if we suspect that freezing cold, blistering heat, and suffocating humidity can take a toll on an instrument (or the stability of a chemical compound or biological sample), how do we quantify it? The answer is: environmental test chambers.

Environmental test chambers: background

Environmental test chambers, also known as environmental simulation chambers, are designed to measure the wear-and-tear of simulated environmental conditions on a test sample. In addition to heat and humidity, test chambers can also simulate varying degrees of light, air pressure, and physical movements such as vibrations. Such simulations can model external, weather-related conditions, as well as physical motions that mimic the use that the product might experience by people or in conjunction with other components (depending on the nature of the product).

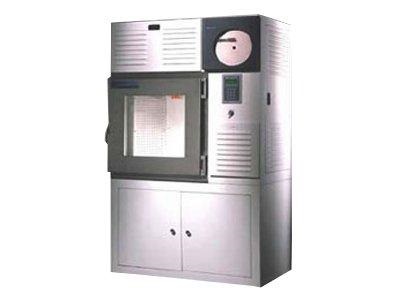

Reach-in Calibration Chamber from Parameter Generation and Control.

Reach-in Calibration Chamber from Parameter Generation and Control.

Applications

Environmental test chambers are used to simulate environmental conditions, and assess the damage caused by them, on test subjects. This process is important for manufacturers who want to be sure that the products they offer to the public will have a reasonable lifetime expectancy. Also, such testing helps to determine the environmental conditions in which a product functions optimally, as well as the environmental conditions that are best to avoid. Environmental test chambers also help to estimate the expected lifespan of a product. They can simulate the “aging” of the product and help to anticipate potential problems that may occur as the product ages.

Environmental test chambers are also used in the chemical industry to determine the stability of chemical compounds, or biological samples, in different types of conditions. For example, such testing helps chemists or biologists learn how long a chemical or biological sample will remain active under particular environmental conditions. Likewise, the food industry can use environmental test chambers to determine the lifetime or safe shelf life of food products when stored in different conditions.

Range of instrumentation and measurements

Even though environmental test chambers can model a wide range of conditions, most test chambers are designed to simulate a specific subset of features. However, the possible features are many, so careful consideration of the exact nature of the conditions you want to simulate is wise. Here are some examples of conditions that environmental test chambers can simulate:

Extremely cold or hot temperatures

- Changes or jumps in temperature

- Specific humidity levels

- Changes or jumps in humidity

- Rain

- Submersion in water

- Salt water or salt spray

- Visible light exposure

- Ultraviolet radiation

- Infrared radiation

- Electromagnetic radiation

- Vacuum conditions

- Vibrations and other physical motions.

Purchasing considerations

When looking for an environmental test chamber, several important points warrant consideration. One is the dimensions of the objects of study, since they must fit within the chamber’s interior. Environmental test chambers vary in size, which is closely related to the size and shape of the object that will be tested. Some environmental test chambers for smaller objects might be appropriate as benchtop instruments, while another type of test chamber for much larger objects might actually be a specially equipped room. It is also important to check whether the chamber will supply the humidity levels that you will need. A wide range is available, with relative humidity levels up to 98% if needed.

Other considerations are the temperature range, the accuracy of temperature controls, and how quickly the temperature within the chamber can be changed if needed. Environmental test chambers can feature a wide temperature range (for example, –70 to 180 ºC), while others with more dedicated uses might be narrower. If your plans do not include testing at extreme temperatures, choosing a model with a narrower temperature range might possibly be more affordable. Also, some models have highly precise set temperatures, with set temperatures to within 0.1 ºC, and uniform chamber temperatures to within 0.5 ºC, while others need not be so precise (i.e., perhaps within 2 ºC).

To maintain tight temperature controls, some environmental test chambers have a heating and cooling system that works by circulating air through the chamber’s interior. Temperature-controlled air may emerge from openings in the sides of the chamber’s walls, which helps to ensure uniformity at different levels of the chamber (this is especially important if the chamber contains shelving). Horizontal airflow minimizes temperature differences between shelf levels, whereas vertical airflow may result in nonuniform interior temperatures. However, there may be some instances when vertical airflow is desired; if you need this feature, look for environmental test chambers that offer the option to switch between horizontal and vertical airflows.

Yet another consideration is the level of sophistication of the controls. Maybe you need only simple controls that specify only one setting at a time, and can be changed manually. More complex environmental test chambers might include digital, programmable controls that allow you to specify a series of conditions that change over time. Some models are web-enabled for remote monitoring, so that you can keep track of your experiments from your lab, desk, laptop, or smartphone.

Another consideration is safety features, such as visual and/or audible alarms to signal if a feature (such as temperature or humidity) changes by more than an acceptable amount from the desired setting (more than an acceptable variation in ºC for temperature, or % relative humidity, for example). Many models also offer some means to view the interior of the environmental test chamber for visual inspection during testing. This may be as simple as a viewing port in the door or wall. Other models may include a more sophisticated viewing system with a port for a camera that can provide remote visual inspection from virtually anywhere.

Another safety feature is an automatic shut-off that protects the test sample in the event of a test chamber malfunction (so you don’t bake or freeze your sample accidentally). If the regulatory controls fail and, for example, the temperatures go below or above the preset safety points, the environmental test chamber will shut itself down. Some models may not shut down entirely, but instead cease only the malfunctioning component of the chamber. For example, if the temperature exceeds the setpoint, it may shut down just the heating element, while if the temperature falls below the setpoint, it may shut down just the cooling element.

Table 1 – Environmental test chamber manufacturers

Energy-saving, “green” features are attractive to save both resources and costs. This is especially true for those using room-sized environmental test chambers that consume more energy to cool or heat, for example, than does a test chamber the size of a microwave oven. Green innovations have produced “environmental control rooms” that can be cooled using lake water rather than air to reduce costs.

Recent developments in environmental test chambers

For those interested in the cutting-edge software controls available for environment test chambers, check out the WeatherEze® software developed during a cooperative research and development agreement between Percival Scientific (www.percival-scientific.com) and the Agricultural Research Service of the United States Department of Agriculture (USDA). WeatherEze integrates the USDA’s environmental simulation models with Percival Scientific’s environmental test chamber control software.

The result is software that hearkens back from a science fiction novel. Select a location anywhere on earth, and WeatherEze can tell your environmental test chamber to simulate the 30-year average weather conditions— temperature, humidity, and lighting—of that particular location (the North Pole? Hawaii? Paris?). You can select your location by entering latitude and longitude numbers, or just by clicking on a map. Or you can even tell WeatherEze to simulate the actual real-time weather conditions for any place on earth.

Even if your test samples don’t require something as exotic as weather experiences from around the globe, rest assured that other, more conventional control programs for environmental test chambers are just as sophisticated (and are nearly always included with the chamber). By perusing the available offerings, there is an excellent chance that you’ll find an environmental test chamber that is right for you.

A partial list of manufacturers of environmental test chambers is given in Table 1.

Please see our Environmental Chambers / Environmental Test Chambers section to find manufacturers that sell these products

Caitlin Smith is a freelance science writer who has a Ph.D. in Neuroscience from Yale University and postdoctoral work in Electrophysiology and Synaptic Plasticity; e-mail: [email protected] .