Featured Article

Please see our Ultrasonic Homogenizer / Laboratory Homogenizers (Sonicator) section to find manufacturers that sell these products

Laboratory ultrasonic homogenizers or sonicators operate on a system of high-intensity ultrasonic waves. These ultrasonic waves create small vacuum bubbles in the liquid. When the bubbles attain a volume at which they can no longer absorb energy, they collapse violently during a high-pressure cycle. This phenomenon is termed cavitation.

Sonicators have wide-ranging applications including:

- Producing emulsions or uniform dispersions of micron-size or nano-size materials

- Removing viruses from infected tissue

- Breaking down particles and microorganisms

- Degassing liquid

- Enhancing polymerization and chemical reactions.

A sonicator has three main components: a generator, a transducer, and a probe.

The generator transforms the input electrical power to an electrical signal that drives the transducer. The transducer converts the electrical signal into a vibration. This vibration is amplified as a longitudinal vibration in the probe tip, causing the sample to cavitate. Cavitation creates the ultrasound energy, which causes the sample to disrupt and break down into smaller particles.

Types of sonicators

Sonicators can be benchtop or handheld. Handheld sonicators can be stand-mounted. Some sonicators come with dual mechanical and ultrasonic processing. Since cavitation is the cause of the noise inherent to sonicators, some sonicators are supplied with an integrated noise control abatement chamber.

Representative handheld sonicators include the UP50H from Hielscher Ultrasonics GmbH (www.hielscher.com) and the Stuart® SHM1 and Stuart SHM2 from Bibby Scientific Ltd. (www.bibby-scientific.com). The Stuart SHM2 can be stand-mounted.

The VCX130 from Sonics & Materials (www.sonics.com), which is distributed by MIDSCI (www.midsci.com), is a benchtop sonicator.

The DPS-20 from Pro Scientific (www.proscientific.com) is a dual processing sonicator that combines mechanical and ultrasonic sonication, which can be used dependently or independently of each other within a programmable or manual mode.

Considerations for purchasing a sonicator

Choosing a sonicator is a complex process. Factors to consider include the type of applications for which the unit will be used, the motor power, the probe size, and the probe material.

Applications

Most sonicators are applicable to sample preparation, dispersion, cell lysing, desegregation, homogenization, and particle size reduction.

The VCX130 has broader applicability to soil testing, transesterification, nanotechnology acceleration of chemical reactions, degassing, and atomization.

Motor power

Motor power determines the size of the sample to be processed. A small sample does not need high power because the size of the probe will be small and the intensity of a smaller probe is much higher than a larger probe. A sample with higher viscosity may require a higher power to produce results, since the sonicator has to drive a larger probe with less intensity or energy at the tip.

Probe size

Probes come in different diameter tip sizes. A tip with a very small diameter will have a very high intensity for processing because all the energy focuses on a very small area. However, the size of the tip will limit the area of the cavitation, which will limit the sample size. A larger tip will have a lower intensity as the energy spreads out over a larger surface area. However, the area of cavitation or processing area is larger, thus allowing for more of the sample to be processed.

Probe material

Probe material includes titanium, stainless steel, and polycarbonate.

Representative sonicators with a titanium probe include the Omni Ruptor 250, Omni Ruptor 400, and Omni Ruptor 4000 from Omni International (www.omni-inc.com).

An example of a sonicator with a stainless steel and disposable polycarbonate probe is the Stuart SHM2.

Noise level

Since cavitation is the cause of the noise inherent to sonicators, some sonicators come with an integrated, noise control abatement chamber. An enclosure for noise control and abatement can also be added to benchtop sonicators.

The Omni Ruptor 4000 includes an integrated sound abatement chamber with a clear Plexiglas door to reduce the cavitational sound emitted during processing.

Sonicator models

• The VCX130 from Sonics & Materials processes samples from 150 μL to 150 mL in applications such as sample preparation, dispersion, cell lysing, desegregation, homogenization, particle size reduction, soil testing, transesterification, nanotechnology acceleration of chemical reactions, degassing, and atomization.

• The Stuart SHM1 and Stuart SHM2 sonicators from Bibby Scientific Ltd. process samples in the 0.03-mL to 20-L range in such applications as tissue homogenization, cell disruption, emulsions, suspensions, and protein extraction.

• Omni International’s Omni Ruptor 250, Omni Ruptor 400, and Omni Ruptor 4000 sonicators process samples in the 0.25- mL to 1000-mL range in applications including disruption of cells, bacteria and spores, emulsification of immiscible liquids, homogenization, uniform dispersion of particles in liquids, acceleration of reactions, depolymerization of large molecules, and degassing of liquids.

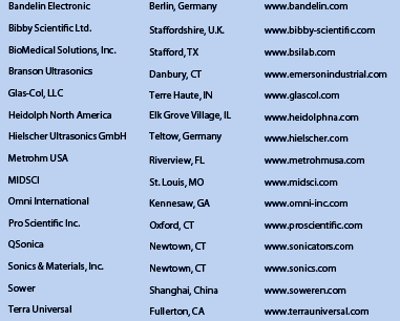

Table 1 – Sonicator providers

• The DPS-20 mechanical/ultrasonic homogenizer from PRO Scientific Inc. processes samples in the 1.5-, 2-, 15-, 16-, 19-, and 50-mL range, and up to 20 samples can be processed in one run.

• Heidolph North America’s (www. heidolphna.com) SilentCrusher M Homogenizer is for processing samples from 0.8 to 2000 mL. This sonicator comes with 13 different sterilizable generators from 6 to 22 mm in diameter.

• Terra Universal Inc. (www.terrauniversal. com) distributes the Q55 and Q700 sonicators from QSonica (www.sonicator. com) for processing samples in the 200-μL to 50-mL range in applications such as cell disruption, emulsion creation, DNA shearing, and homogenization.

Latest developments

An alternative to ultrasonic homogenizers are bead mill homogenizers. Bead mill homogenizers rely on the mechanical impact between beads and the sample inside sealed tubes. They have applicability for human, plant, animal, and microbial sealed samples and can process multiple small-volume samples at one time.

Sonicator providers

A list of companies that sell sonicators is given in Table 1.

Please see our Ultrasonic Homogenizer / Laboratory Homogenizers (Sonicator) section to find manufacturers that sell these products

Lina Genovesi, Ph.D., JD, is a Science, Business, and Regulatory Writer based in Princeton, NJ; e-mail: [email protected] ; www. linagenovesi.com..