Featured Article

Please see our GC MS Instrument section to find manufacturers that sell these products

Gas chromatography/mass spectrometry (GC/MS) is a highly selective analytical technique for identifying compounds using mass detection. As in liquid chromatography (LC), gas chromatography relies on a mobile phase, but in GC, the mobile phase is a gas, not a liquid solvent. Although not as widely used as LC/MS, GC/MS is a powerful tool for identifying unknown compounds, offering high resolution and an abundant archive of chemical and electron ionization profiles. As a molecular fingerprinting method, GC/MS is well suited for bioanalytical, forensic, clinical, pharmaceutical, petrochemical and environmental applications, among others.

Historical development of GC/MS

James and Martin developed and demonstrated gas–liquid chromatography in the 1950s. The concept of utilizing a mass spectrometer as a detector with gas chromatography was realized in the 1950s by Gohlke and McLafferty. GC/MS coupling was first demonstrated by Holmes and Morrell in 1957, who used an oscilloscope and a mass spectrometer to observe the behavior of an effluent from a GC column.

Packed-column GC interfaces were developed over the next decade to reduce carrier gas transfer from GC samples, mitigating the high pressure required for GC into a form that was more compatible with interpretation with the MS component of the systems. Capillary columns and other gas interfaces ensure a reliable stream of ions into the MS component of the GC/MS. The first commercial GC/MS system was a magnetic instrument developed by LKB in the 1960s; Hewlett-Packard introduced the first quadrupole instrument in the early 1970s.

Principles of GC/MS

As with most analytical techniques, keen attention to sample preparation and solvent choice is critical for GC/MS analysis, as sample contamination or degradation may result in a loss of MS sensitivity. Techniques for GC/MS sample preparation include solid-phase extraction (SPE), liquid-toliquid extraction (LLE) and solid-phase microextraction (SPME). Advances in column technology reduce the time required for sample preparation because users can purchase columns that eliminate steps and produce faster results.

GC/MS analysis

A high-pressure, high-temperature gas (typically helium) within the GC column carries the sample. A temperature-controlled “oven” houses the GC column. Capillary GC columns significantly slow sample flow rates, allowing the GC column to interface directly with the mass spectrometer. Important factors that influence the time required for a gas separation to occur within a GC column are:

- The characteristics and preparation of the sample analyte

- Type of stationary and mobile phases used

- Temperature control

- Column design

Sample ionization from GC to MS output

Analyte molecules are first ionized; electron ionization (EI) and chemical ionization (CI) are commonly utilized. In electron ionization, a beam of electrons is applied to the analyte after it is introduced into the GC. This results in the loss of an electron from the analyte molecule, creating a molecular ion (M+) and molecular fragments. The molecular ion identifies the molecular weight of the substance as a peak in the mass spectrum.

Mass analyzers: technology and benefits

Mass analyzers separate ions based on their mass-to-charge ratio, or m/z. The analyzers (listed below) serve as filters to separate ions from an ionized molecule and, consequently, send fragmentation data to a mass spectrometer. The mass spectrometer interprets the ion data as electrical signals that are arranged into peaks in a chromatogram. Typically, a greater concentration of a compound translates to a larger peak, or identifying signal.

- Linear quadrupole analyzers are commonly used on board GC/ MS instruments. Also known as triple quadrupole or monolithic hyperbolic quadrupole analyzers, these instruments comprise four electromagnetic rods arranged in a square pattern to which radiofrequency (rf ) and direct-current (dc) potentials are applied. Increased rf and dc potentials in this configuration result in a faster scanning rate and lowered testing costs.

- Ion trap analyzers incorporate a high-pressure gas such as helium to stabilize the path of ions within the analyzer. The analyzers work as three-dimensional quadrupoles; ions run from the ion source in pulses, and fast scanning of the rf frequency results in rapid output of spectral scan data.

- Time-of-flight (TOF), or quadrupole TOF, analyzers offer high scan speed and accuracy. The principle of TOF is the separation of ions by their acceleration over an electrical field. Ions with a lower m/z travel most quickly through the field, followed by those with a higher m/z.

- Magnetic sector analyzers are known for their high mass resolution. These analyzers utilize an electromagnetic field to separate ions in space according to the radius of their trajectories. An electrostatic analyzer narrows the kinetic energy spread of the ion beam, giving it the oft-used name “double-focusing spectrometer.”

Choosing a GC/MS instrument

Combined instruments such as GC/MS systems are now faster and more compact. Today’s instruments are cross-compatible and offer a range of analytical capabilities.

Before purchasing a GC/MS system, one should consider the following:

- Can existing equipment and software be used (e.g., is it possible to fit an existing GC instrument with an MS adapter?)

- Benchtop space and predicted throughput

- Desired operating temperature range of the column apparatus (ion sources and mass analyzers can run at significantly different temperatures)

- Mass range capacity for measuring samples

- Portability (can the instrument be used in the field?)

- Type of ionization method/mass analyzer that best suits the intended application (e.g., environmental, food analysis, petrochemical, pharmaceutical).

Table 1 lists various GC/MS technologies, applications and principles of operation.

Table 1 – GC/MS technologies, applications, principles of operation and example systems

Adapting a mass spectrometer to an existing GC instrument

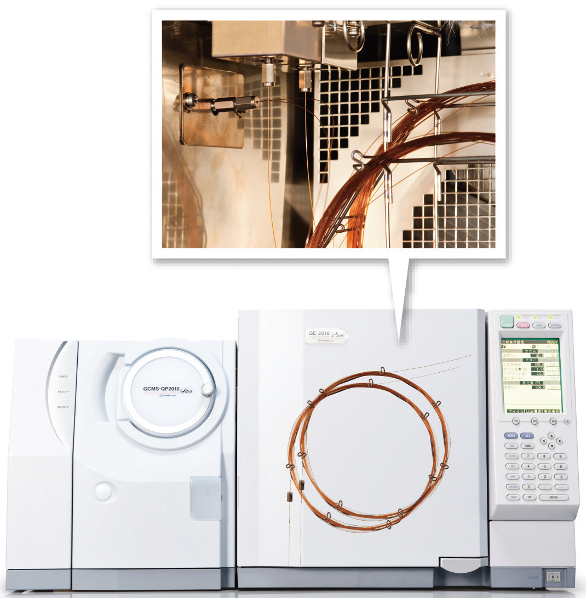

Figure 1 – GCMS-TQ8040 Triple Quadrupole GC/MS/MS from Shimadzu.

Figure 1 – GCMS-TQ8040 Triple Quadrupole GC/MS/MS from Shimadzu.Some vendors provide the option of retrofitting an existing GC with a high-resolution or high-throughput TOF/MS. Markes International (Cincinnati, Ohio) offers the BenchTOF TOF/MS adapter. The Pegasus HT TOF/MS from LECO (St. Joseph, Mich.) is another example.

Expanded column technology

Modern GC/MS testing benefits from improved instrument couplings, analytical software and column technology. A new GC stationary phase, “ionic liquid,” was introduced in 2008. Ionic liquids are capable of being used for multidimensional separations, lending to their orthogonality and temperature stability. Supelco (St. Louis, Mo.) offers a comprehensive line of ionic liquid GC columns. Ultra-inert GC/ MS columns, such as the Ultra Inert line from Agilent, respond to increasingly lowered detection limits by greatly reducing the surface activity that might impede detection sensitivity at the mass analyzer. The Twin Line GC/MS (Figure 2) from Shimadzu enables simultaneous connection of two capillary columns.

Figure 2 – Shimadzu’s Twin Line GC/MS.

Figure 2 – Shimadzu’s Twin Line GC/MS.GC/MS variants for specific operations

The ease of use and capabilities of GC/MS instruments have been enhanced over the past few years. Thermo Fisher Scientific plans to release a GC/MS system paired with Orbitrap technology. Orbitrap MS technology utilizes “orbital trapping” of charged molecules in electrostatic fields for injection into the MS.

Cryo-focusing GC/MS (cryo-GC/MS) is being utilized for complex observations, such as analyzing the degradation of molecules. The Thermo TSQ 8000 Evo-GC-MS/MS features cryo options to –100 °C.

Systems are faster and more sensitive than ever; for example, the AccuTOF-GCx from JEOL (Peabody, Mass.) features extremely high sensitivity (S/N>300 at OFN 1 pg/μL). Some systems offer the option of different ionization methods, such as field desorption (FD), field ionization (FI), EI/FI/FD and liquid injection field desorption ionization (LIFDI). LECO and AB SCIEX (Framingham, Mass.) have partnered to provide GC/TOF and LC/QTOF MS systems for metabolomics studies.

Emilia Raszkiewicz is managing editor, American Laboratory; [email protected]

Please see our GC MS Instrument section to find manufacturers that sell these products