A growing need for quality control (QC) and quality assurance (QA) has generated an demand for mechanical testing equipment. Things as diverse as whether a rubber band will stretch and whether a bridge will collapse under the weight of a car can be determined by mechanical testing. Some types of mechanical test equipment run adhesion, compression, fatigue, flexure, ductility, shock, tensile, vibration, and shear tests to make sure that the material being tested will work and behave in the appropriate way.

Range of Instrumentation

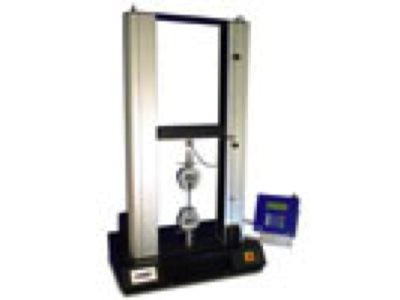

Various product types have been developed for mechanical testing, which include fatigue testers for fatigue resistance measurement; hardness testing equipment; tensile testers ; compression testers; and more. The premise for this range of instrumentation is to apply variations of stress and strain for quality control and assurance.

Friction testers, scratch testers, and tribometers are used for performance measurement of static and kinetic friction coefficients, adhesion, surface scratch hardness, stickiness, tensile strength, peel resistance, wear, and lubrication. Systems for both linear and rotational testing are available, in configurations including pin-on-disk, disk-on-disk, ball-on-flat, ball-on-disk, and linear reciprocating.

Applications

Mechanical testing equipment is used in many fields.

- Material testing, including rubber, ceramics, plastics, metals, etc.

- Biomedical devices

- Construction

- Manufacturing

- Automotive

- Civil engineering

- and more

What to consider when choosing mechanical testing equipment?

When choosing mechanical testing equipment, it is important to know the parameters that need to be tested. Not every item produced needs every type of mechanical test. The temperature and humidity of the environment in which the mechanical test equipment will be used should also be taken into consideration. Some other features that can vary among equipment are the user interfaces and the display options.

Many of today’s instruments offer interchangeable test fixtures, or jigs, that connect to the base instrument, giving the user the ability to measure multiple characteristics on a single test station. Integrated software, single and repeat testing, temperature control, atmosphere and liquid control, and variable rotational speeds enhance usability.

Click on the links below to discover and compare mechanical testing equipment from various manufacturers: