Featured Article

Circulating baths are the universal choice for temperature control of test samples when performing viscosity measurements in R&D or QC laboratories. They provide flexibility for viscosity testing using a beaker or similar container with sample immersed directly in the bath or circulating bath fluid to an external device with sample that controls temperature. Examples in Figure 1 illustrate the two approaches.

Figure 1 – a) Beaker immersed in bath for viscosity test. b) Circulating bath provides temperature control for sample contained in viscometer accessory.

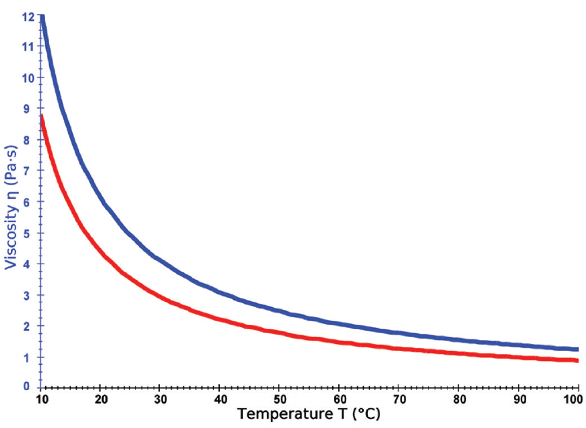

Figure 1 – a) Beaker immersed in bath for viscosity test. b) Circulating bath provides temperature control for sample contained in viscometer accessory.It is important to note that viscosity of all materials is a temperature-dependent phenomenon. The graph in Figure 2 illustrates how viscosity decreases as temperature increases. When specifying a test method, it is necessary to define the control temperature when measuring sample viscosity. Use of the term “ambient” is too general because labs are not maintained at a single temperature. If air conditioning is available, lab temperature may be somewhere between 20 and 25 ºC. Some labs experience a change in temperature during the day as the outdoor environment warms up. All of these considerations confirm that the best test approach when measuring viscosity is to use the bath for temperature control of the sample.

Figure 2 – Viscosity versus temperature profile for test sample.

Figure 2 – Viscosity versus temperature profile for test sample.Test technique for conditioning sample temperature is another detail that merits discussion. Different materials achieve temperature equilibrium at various time intervals. Volume of test sample has a direct bearing on the amount of time needed to reach the control temperature. The most commonly used temperature for viscosity testing in QC labs is 25 ºC. By contrast, R&D is more likely to create the viscosity versus temperature profile shown in Figure 2 because this information is necessary for complete material characterization. R&D will typically specify a single control point for sample temperature when handing off the viscosity test method to QC.

Given the reality that viscosity testing of material in a beaker will require a greater amount of time for proper temperature control, QC labs prefer to use viscometers with accessories that require small sample volumes. The device attached to the viscometer in Figure 1b, for example, is called a Small Sample Adapter (SSA) and uses 16 mL or less of sample material for the viscosity test, depending on the size of the spindle that fits into the chamber. Note that the circulation hose connecting the bath to the SSA attaches to ports at the top and bottom of the water jacket. The feed line connects to the bottom port. This allows circulating fluid to completely fill the jacket before being returned out the top port back to the bath.

Some viscosity tests require precise temperature control with allowable deviation <0.1 ºC. If there is a significant temperature difference between the lab environment and the control point, it may be necessary to insulate the circulating hose to minimize heat transfer. Embedded sensors in the sample chamber monitor temperature continuously and provide a control loop function to the circulating bath to adjust temperature as needed.

Best practices to ensure that bath performance meets the laboratory’s needs for precise temperature control include the following:

- Inspect and clean the bath air filter per the manufacturer’s specification

- Treat the circulating fluid in the bath with algicide to keep the bath clean and odor-free

- Check the ports on the circulating bath and use hose clamps for a secure connection

- Position viscosity test equipment away from the air exhaust port on the bath

- Use a calibrated temperature probe to confirm the bath fluid temperature in the tank

- Specify bath accessories as needed to ensure best test results (see Figure 3).

Figure 3 – Bath accessories.

Figure 3 – Bath accessories.Robert G. McGregor is director, Global Marketing & High End Lab Instrument Sales, AMETEK Brookfield, Instrumentation & Specialty Controls Division, 11 Commerce Blvd., Middleboro, MA 02346, U.S.A.; tel.: 800-628-8139/508-946-6200; fax: 508-946-6262; e-mail: [email protected]; www.brookfieldengineering.com

Related Products