Weighing is one of the first steps in an analytical process and has a strong bearing on the final results. A balance must be consistently accurate; otherwise analytical standards and thus the analytical results will be in doubt. This is critical in forensic laboratories where a verdict can depend on the amount of evidence weighed and proof that the weighing data is complete and traceable. Therefore, weighing results must be free of doubt and withstand any challenge in court.

Significance of measurement uncertainty and minimum weight

Forensic laboratories handle trace evidence, drugs, fire, and explosive residues, as well as examine unknown substances, fingerprints, and documents. Amounts of any substance used for testing must be carefully tracked to ensure that evidence is not tampered with. Minute inaccuracies, or any change in weight that is not accounted for, can mean the difference between reliable and unreliable evidence.

Weighing is a critical step in forensic investigations for qualitative and quantitative drug analysis. It strongly influences the overall quality and integrity of the final result because the net weight and purity (depending on statutes) often have a direct correlation to the length of sentence handed down. To ensure weighings are accurate, laboratory managers often rely on the quality management system to define a weighing process. This includes proper recording criteria and determination of measurement uncertainty. A concept that has not been incorporated into many forensic institutions is the calculation of the minimum sample weight, often referred to as the minimum weight. This concept provides an additional level of security and ensures proper weighing results.

To better understand minimum weight, it is important to recognize that the critical prerequisite for traceable and accurate weighing is the effective calibration of weighing instruments, which should also include an estimation of measurement uncertainty. Historically, many laboratories have set up their own calibration procedures due to the lack of nationally or globally recognized calibration guidelines. Based on international cooperation from subject-matter experts in the field of metrology, efforts have been made to globally harmonize the methodology of calibration of weighing instruments.1

The benefit of these harmonization activities is that the state-of-the-art calibration concepts not only stipulate how to estimate measurement uncertainty at the time of calibration, but provide guidance for estimation of uncertainty during the day-to-day usage of the instrument. This leads to the calculation of the minimum sample weight, which is the smallest amount of net substance that should be weighed in order to achieve a specified degree of accuracy.

All weighing instruments act in a similar manner across the weighing range—as the sample size decreases, the relative measurement uncertainty increases. Eventually, with a small enough mass, the relative weighing uncertainty can become high enough that the weighing result is no longer accurate. The measurement uncertainty then becomes larger than the specified threshold. This accuracy limit is the minimum weight (Figure 1). Based on the risk associated with the weighing process, it is also recommended to apply a safety factor to this value. This factor increases the minimum amount that should be weighed on a particular balance. The increased safety factor accounts for performance fluctuations caused by environmental factors (air drafts, temperature, vibrations, and different user techniques) that can affect the balance during normal use between calibrations.

Figure 1 – Typical behavior of measurement uncertainty across the weighing range of a balance.

Figure 1 – Typical behavior of measurement uncertainty across the weighing range of a balance.The minimum weight is an extremely important characteristic when performing quantitative analysis in a forensic environment because small sample sizes are often used in standard preparation for the purpose of minimizing costs. The associated weighings of the standards also have a direct impact on the calibration curves performed on an HPLC or GC, which are used to determine the purity of substances such as methamphetamine. Therefore, weighing above the minimum weight is critical because it could impact the accuracy of the linear curve and the end purity of the confiscated substance, resulting in over- or undersentencing.

With the benefit of measurement uncertainty and the resulting minimum weight defined, it is important to realize that typical calibration certificates only contain measurement uncertainty values. An Accuracy Calibration Certificate (ACC) has both components. Additionally, it links the performance of the weighing instrument to the weighing process tolerances required by the user for a specific application. An ACC allows the safe weighing range to be determined for each particular balance. This starts at the minimum weight and extends to the maximum weighing range of the device. Therefore, the safe weighing range establishes what amounts can be weighed accurately to meet specific user requirements. This level of detail from a calibration enables balance users to improve the quality of their weighing, increase confidence in the weighing results, and avoid weighing errors.

Ultimately, understanding and implementing a quality system that adheres to weighing more substance than the minimum weight ensures instrument accuracy and minimizes the risk of errors that could impact the correctness of convictions.

Avoiding incomplete data and achieving compliance

To help comply with and meet the requirements set forth by accreditation bodies, it is also important to understand the benefits of incorporating the components of the weighing process into an integrated data management system. In recent years, an increasing number of assessments and internal audits have revealed incomplete data, a lack of audit trails, and falsification of results. While most labs have turned toward LIMS with the idea of replacing the manual workflow, these systems are designed primarily to aggregate results data from an array of analytical tests, rather than to automate and document benchtop workflows or bind instrument metadata to the measurement.

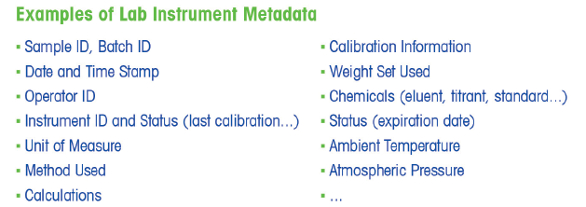

With respect to measuring instruments, many regulation guidelines require laboratory records to include complete data derived from all tests necessary to assure compliance with established specifications and standards.2 This includes the raw data generated through the course of an analysis and the associated metadata. Metadata is the contextual information required to understand data.3

An example of the use of metadata in an everyday situation is shown in Figure 2. If a car speeds through a traffic enforcement camera and the only information captured is the image, speed of the automobile, and the associated unit of measure, there is not enough information to link the car to the speed. However, if the date, time, color of the car, unique picture identifier, and location are included, the necessary contextual information is then available to associate the car with the speed.

Figure 2 – Example of metadata in an everyday situation.

Figure 2 – Example of metadata in an everyday situation.When the same principle is applied to the forensic laboratory, every critical weight measurement that is recorded should not only include the weight and unit of measure, but the additional metadata necessary to be considered “complete data” (Table 1).

Table 1 – Examples of metadata available from laboratory instrumentation

Automated data transfer and standardizing weighing workflows

Many labs have discovered that transferring metadata from benchtop analytical instruments is much more complex than the transfer of only a few parameters, such as sample weight or unit of measure. Leveraging the potential of appropriate software technology such as LabX (Mettler-Toledo, Columbus, OH) enables users to transfer weighing results with all the associated metadata directly to their LIMS, thereby ensuring the data is complete and traceable.

Additionally, the weighing workflow can be automated and standardized to the specifications of the unit or lab (Figure 3). This proves that the same weighing process is used for each sample, regardless of who performs the steps, ensuring consistency in every analysis. For example, the administrator can elect to have the balances locked down every morning until an analyst logs in and performs a routine test with traceable weights. Only after its completion can the balance user proceed to a guided weighing process on the terminal of the balance.

Figure 3 – Example of a standardized weighing method.

Figure 3 – Example of a standardized weighing method.Another benefit provided by the software is the ability to capture not only the net weight of the substance, but the weight of the tare vessel used in each weighing event. This allows the analyst to provide documentation during trial, confirming the tare vessel weight was not included in the net weight of the substance in question.

Conclusion

To stay compliant with ever-changing regulations and withstand any challenge in court, it is critical for managers and scientists in forensic laboratories to be well-informed about the key issues surrounding weighing accuracy and data integrity. Forensic laboratories can achieve the ultimate goal of eliminating errors, simplifying processes, and demonstrating regulatory compliance by:

- Establishing a harmonized approach to the calibration of balances

- Ensuring all weighing is performed in the safe weighing range, and well above the minimum weight

- Automating data capture and transferring weighing data to ensure complete and traceable data.

References

- EURAMET, Guidelines on the Calibration of Non-Automatic Weighing Instruments, No. 18, Version 4.0, November 2015; https://www.euramet.org/Media/docs/Publications/calguides/I-CAL-GUI-018_Calibration_Guide_No._18_web.pdf

- U.S. Food and Drug Administration, Code of Federal Regulations, Title 21, Food and Drugs, Pt. 200-299, revised 21 CFR 211.194 (a); https://www.accessdata.fda. gov/scripts/cdrh/cfdocs/cfcfr/CFRSearch. cfm?fr=211.194

- U.S. Food and Drug Administration, Pharmaceutical Quality/Manufacturing Standards (CGMP), Data Integrity and Compliance with CGMP, Guidance for Industry, April 2016; https://www.fda.gov/downloads/Drugs/GuidanceComplianceRegulatoryInformation/Guidances/UCM495891.pdf

Tucker Rubino is market specialist, Klaus Fritsch is manager compliance and senior metrologist, and Thomas Rohrer is business development manager, Mettler-Toledo, LLC, 1900 Polaris Pkwy., Columbus, OH 43240, U.S.A.; tel.: 614-438-4511; e-mail: [email protected]; www.mt.com