Featured Article

New spectroscopy platforms give scientists more ways than ever to identify unknown materials

To analyze materials, scientists often use spectroscopy. Devices that utilize spectroscopy vary in many ways, especially the wavelength of light that the platform collects from a sample. This article explores advances in near-infrared (NIR) and IR techniques.

To identify an unknown material, scientists often use IR spectroscopy. In particular, IR spectroscopy can identify functional groups, which makes it easier to determine the identity of raw materials, as well as contaminants. “In addition to the classical use of IR, new sampling techniques in combination with more ruggedly designed interferometers now allow FTIR to be used for quantitative measurements, as well as identification through library searching,” says Shannon Richard, manager of Fourier transform infrared (FTIR) spectroscopy products at Agilent Technologies (Santa Clara, CA).

Other advances in IR platforms also expand their capabilities. As Richard points out: “Advancements in computer processing allow for expanded and advanced data processing, chemometrics, and neural-network processing, which can now be quickly accomplished through the speed and processing power that is accessible on everyday computers—no longer requiring a supercomputer to do advanced mathematical algorithms.”

Fast-paced improvements in FTIR

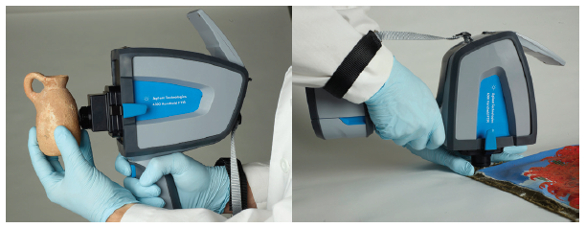

Some key technical advances make it possible for scientists to use FTIR in more places. “The past decade has seen an increase in the ruggedness of the interferometers, and also the miniaturization of the optics used in FTIR spectrophotometers, as can be seen in many field or handheld applications where on-site or in-situ analysis is desired,” Richard explains. “By utilizing the FTIR system at the point of sample, the needs of the customer can be addressed immediately without needing to send a sample back to the lab.” Some handheld FTIR devices only weigh 2.5 kilograms, and that includes the on-board analysis.

In looking at what lies ahead for FTIR, Richard talks about the light source. She points to “a new class of optics that is being used for source elements in instruments instead of the traditional ‘Glow Bar’ emitter sources that have traditionally been used in FTIR spectrophotometers,” adding, “We are seeing a rise in the research into and use of these high-powered sources.” One example of such a source is a quantum cascade laser (QCL). “With the ability to target narrow spectral ranges and target specific frequencies, the QCL-based systems are being utilized in infrared microspectroscopic analysis for real-time analysis in biomedical, food, and pharmaceutical applications.”

With a QCL or laser-directed IR (LDIR) system, scientists usually get higher spatial resolution and faster analysis than with typical FTIR. “These systems are capable of hyperspectral imaging, allowing the user to image much larger samples in a fraction of the time as standard FTIR microscopes,” Richard notes. “We are already seeing several instruments that are being introduced into the market with this technology.”

One example is the Agilent LDIR Imaging Analyzer, which images in the mid-IR range. For example, it can analyze a drug tablet in seconds and provide data on the active pharmaceutical ingredients, binders, and so forth. This platform can also be used to analyze defects in polymers and multilayer films.

The market for FTIR spectrometers delivers many options, and different platforms excel in various features. For example, ABB (Zurich, Switzerland) gives its MB3000, an FTIR platform, a signal-to-noise ratio of 50,000:1. The Alpha II FTIR Spectrometer from Bruker (Billerica, MA) delivers a ratio of better than 55,000:1.

The Agilent Technologies 4300 Handheld FTIR can test a variety of objects—including pottery and textiles—where needed. (Image courtesy of Agilent Technologies.)

The Agilent Technologies 4300 Handheld FTIR can test a variety of objects—including pottery and textiles—where needed. (Image courtesy of Agilent Technologies.)Shimadzu (Columbia, MD) offers a variety of IR platforms. The IRSpirit is a small enough FTIR platform to carry from one place in a lab to another. Also, Shimadzu and third-party accessories can be added.

NIR analysis

Many spectrometers also offer an NIR option. “NIR spectroscopy is a useful tool for qualitative and quantitative analysis of many organic materials, ranging from food commodities to pharmaceutical dosage forms,” says Ryanne Palermo, a market manager at BUCHI (New Castle, DE) and an expert in NIR spectroscopy. “The technique offers many advantages over traditional wet-chemistry testing methods.” As examples, she points out that NIR spectroscopy can be fast. “Properties—such as the percentage of fat, protein, or moisture—may be measured simultaneously and in a matter of seconds,” Palermo says. “An NIR method is also nondestructive—samples are neither consumed nor altered during testing, allowing for further testing as desired.”

The BUCHI NIRMaster works well for at-line quality control of food and feed products. (Image courtesy of BUCHI.)

The BUCHI NIRMaster works well for at-line quality control of food and feed products. (Image courtesy of BUCHI.)Although NIR is not a new approach to spectroscopy, it keeps improving. “While NIR technology has been used commercially since the 1970s, hardware advances in more recent years include optimized interferometer and diode-array technology,” Palermo says. “Software advances include improved data analysis, such as chemometric functionality and user interfaces.”

On the hardware side, scientists can expect an NIR platform that stands up better than before. “By employing single-beam optics and reducing the use of mechanical parts, which wear and tear and are more subject to vibrational interferences, NIR technology has become more robust, with capabilities for at-line use on the production floor,” Palermo explains. “At-line installations reduce the lag-time between measurement and actionable decisions regarding product quality control—for example, to continue or complete a blending or granulation unit operation.”

Some advances even improve the ability to incorporate NIR analysis directly into production. “Advances in diode-array technology and optics housings have also improved on-line monitoring capabilities, enabling real-time quality control of product moving through the production cycle,” Palermo notes. “Software advances, like calibration wizards and autocalibration functions, have allowed for complex tasks to be accomplished with less expertise in chemometrics, making the technology more accessible and reducing method-development time.”

BUCHI offers a family of NIR platforms. For example, The N-500 FT-NIR spectrometer is modular, with hot-swappable measurement cells convenient for quality control or R&D laboratories. The BUCHI NIRMaster offers a hygienic design with ingress protection, best for at-line quality control of food and feed products. The NIR-Online product can be integrated directly into a production line or unit operation.

Despite some maturity, advances in IR and NIR platforms show no signs of slowing down. With improvements in various hardware components plus software, spectrometers in these categories can do more or weigh less—maybe both at once. With so many options, testing out one or two never hurts. Expect vendors to bring platforms to test with specific samples and to demonstrate data-analysis capabilities. Only then can the right fit be found.

Mike May is a freelance writer and editor living in Texas. He can be reached at [email protected]