Featured Article

For over 20 years, near-infrared (NIR) analysis has been an established method to determine the octane number in gasoline and cetane number in diesel. NIR analyzers are capable of producing accurate results in under 1 minute using a simple procedure. Additionally, portable NIR analyzers have been developed that allow sample analysis to occur anywhere, especially in the field. For convenience, the analyzer can be calibrated for numerous applications, such as octane number for gasoline, cetane number for diesel, and ethanol content for blended fuels. Operation can be as simple as loading a sample cup with fuel, and then pressing a few buttons to produce results quickly.

Mid-infrared (IR) analyzers were developed to determine biodiesel content in diesel fuel. The method to do so is provided in ASTM D7371—Standard Test Method for Determination of Biodiesel (Fatty Acid Methyl Esters) Content in Diesel Fuel Oil Using Mid Infrared Spectroscopy (FTIR-ATR-PLS Method). Instruments that comply with ASTM D7371 have been analyzing biodiesel content in diesel fuel for a number of years, and provide rapid analysis in the laboratory. However, some fuel analyzers utilize the NIR wavelength range opposed to the mid-IR range that is used in ASTM D7371. Therefore, it would be beneficial if the NIR region could determine the biodiesel content of diesel fuels, so that existing NIR analyzers could be calibrated to include biodiesel content testing. Figure 1 shows a graph of far-, mid-, and near-IR spectra.1

Figure 1 – The infrared spectrum.1

Figure 1 – The infrared spectrum.1To provide accurate analysis, NIR instruments need a reliable calibration process. For mid-IR analyzers, ASTM D7371 separates the biodiesel calibration into three calibration ranges. One range, Set A, is for low biodiesel content, where low biodiesel is defined as containing less than 10.00 volume% biodiesel in the diesel fuel. The second calibration range, Set B, covers the high biodiesel range with content between 10.00 and 30.00 volume% in the diesel fuel. The third calibration range, Set C, contains biodiesel content from 30.00 to 100 volume%. For each set of samples, the instrument is calibrated in accordance with the guidance provided in ASTM E1655 (Standard Practices for Infrared Multivariate Quantitative Analysis), and two separate partial least squares (PLS) calibrations are developed. By using these strictly standardized calibration sets, the mid-IR instruments are capable of producing accurate results with a stringent calibration process.

ASTM D7371 sets forth a detailed calibration process for the mid-IR spectrum. Since the NIR analyzers do not comply with ASTM D7371, they must have their own calibration process that results in accurate sample analysis, which must be tested and proven to be reliable, with an accuracy that is comparable to ASTM D7371.

Each NIR analyzer is calibrated individually by running calibration standards through the analyzer, then merging the lab results with the optical data. A multiple linear regression can be used to determine the constants for the analyzer. The reduction software generates a set of calibration constants (Kvalues) and descriptive statistics, including the standard error of calibration (SEC) and correlation coefficient (CC).

Some NIR instruments are designed to be used in the field. Therefore, the temperature of the analyzer must be modeled into the calibration. To do this, each calibration standard is run with the analyzer at room temperature, a higher temperature (up to 38 °C), and a lower temperature (down to 5 °C).

It would be best to calibrate on approximately 150 individual calibration temperatures, covering the temperature range. However, it can be difficult to accumulate this large number of analyzed biodiesel samples. Therefore, each sample is tested at the different analyzer temperatures. After the calibration is completed, five independent samples are tested as an accuracy set, which is run at room temperature.

Typical calibration processes are between 0.00 and 30.00 volume% of biodiesel, since these blends are more common in the industry. A typical calibration result is shown in Figure 2 for biodiesel content between 0.00 and 30.00 volume%, which is tested in the NIR range between wavelengths of 810 and 1045 nm.

Figure 2 – Calibration results for biodiesel content between 0.00 and 30.00 volume%.

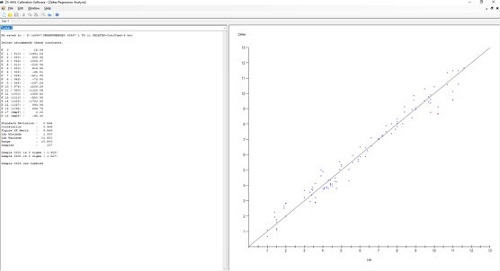

Figure 2 – Calibration results for biodiesel content between 0.00 and 30.00 volume%.Once all of the optical data is collected, the data is split into low and high biodiesel ranges and regressions are done on both ranges. The low biodiesel range is from 1 to 11 volume% biodiesel content, and the high biodiesel range is from 9 to 30 volume% biodiesel content. An example of a multiple linear regression is shown in Figure 3.

Figure 3 – Linear regression of the low biodiesel calibration standards.

Figure 3 – Linear regression of the low biodiesel calibration standards.By using the linear regression, outliers can easily be recognized. Further statistical calculations can be made, such as the standard deviation (SD). The standard deviation low biodiesel samples are summarized in Figure 4, and high biodiesel samples are summarized in Figure 5. Figures 4 and 5 include data from a 14-wavelength portable analyzer, 16-wavelength portable analyzer, and 16-wavelength analyzer.

Using Figures 4 and 5, the standard deviation for the three analyzers can be determined for the full range of the instruments, from 1 to 30% biodiesel, and this is shown in Figure 6.

Figure 4 – Standard deviation of low biodiesel samples.

Figure 4 – Standard deviation of low biodiesel samples. Figure 5 – Standard deviation of high biodiesel samples.

Figure 5 – Standard deviation of high biodiesel samples.The standard deviation is not quite equivalent to what is specified in ASTM D7371, but it is close. With newer samples, it may be possible to achieve the specified standard deviation and accuracy in ASTM D7371 with this NIR instrumentation. Also, the addition of more NIR wavelengths into the test spectrum may also improve the accuracy of the calibration. This is shown in Figures 4–6, where the 16-wavelength portable analyzer is more accurate than the 14-wavelength analyzer with a lower standard deviation. The 16-wavelength portable analyzer is similar in accuracy to the standard 16-wavelength analyzer.

Figure 6 – Standard deviation for full range.

Figure 6 – Standard deviation for full range.Overall, these portable NIR biodiesel analyzers can measure the content of biodiesel in diesel fuel with high accuracy that is near the specified values in ASTM D7371 for mid-IR analyzers. By further refining the calibration process for the NIR analyzers, it is believed that the standard deviation ASTM D7371 specifications can be met.

Reference

- http://www.benjamin-mills.com/chemistry/A-level/IR/

Dr. Raj Shah is a director at Koehler Instrument Company, 85 Corporate Dr., Holtsville, NY 11742, U.S.A.; e-mail: [email protected]; https://koehlerinstrument.com/. Mr. Rosenthal and Mr. Oberg have over 50 years of experience in NIR between themselves.