Biodiesel is touted as a clean and renewable fuel that serves as an environmentally-friendly alternative to petroleum diesel. There are several notable biodiesel updates in the 2017-19 year that will be discussed in this report. Within that year, the National Biodiesel Board (NBB) reported a slight decrease in biodiesel volume production from 2.63 to 2.58 billion gallons. In response, the Federal Renewable Fuel Standard (RFS) program is requiring volume increases for upcoming years. The salient benefits of biodiesel prompted heightened interest to increase percentages of biodiesel in fuel blends. ASTM had willful desires to use biodiesel blends greater than B20 (20% biodiesel, 80% petroleum diesel) in heating oil, electricity generation, and road vehicles to improve productiveness and reduce the impact on the environment.

Under the Biodiesel Task Force ballot review, ASTM had efforts to change fatty acid methyl ester specifications, also known as FAME, which is a bio-component of biodiesel that poses as a contaminate to jet fuel [1]. As a surface-active material, FAME can adhere to pipelines in multi-product distribution systems, leading to cross-contamination of other products [1]. High FAME concentrations can upset thermal stability and alter freezing points, causing engine problems [1]. With those concerns in mind, ASTM raised the allowable FAME concentration limit of 5 ppm to 50 ppm after years of research and testing for safety purposes [1]. Recent updates reveal that ASTM is balloting for an increase in the limit of FAME concentrations in D1655 Jet Turbine Fuel specification to 100 ppm due to cost escalations associated with current FAME requirements and the increasing demand for biofuels [2]. For prudent measures, test protocols were initiated to approve the ballot, and the review could last up to two years. Renewable Fuel Standard, RFS, parties are seeking to transport B5/B20 in multi-product pipelines containing jet fuel, which entices ASTM to swiftly approve the new FAME limit specification.

Biodiesel in the U.S. is commonly produced from raw oils and fats through transesterification where raw materials are reacted with an alcohol, typically methanol, in the presence of a catalyst [3]. ASTM balloted for the update of the percent biodiesel blend test method to also measure raw oil and fat contents. In 2017, the feedstock distribution percentages for biodiesel production were as follows: soybean oil-52%, canola oil-13%, corn oil-13%, cooking oil/recycled feedstock-12%, and animal fats-10% [4]. The percentages of these components in biofuels are important in determining the quality and properties of the biodiesel for blendstock or fuel, which can be used for standardization purposes. For example, fats that are highly saturated, such as animal fats, produce a higher cloud point biodiesel, but better oxidative stability [5]. Biodiesels of high cloud points need to be stored in warm temperatures to avert solidification. Also, fats have significantly less polyunsaturated fatty acids compared to oils, making it less apt to oxidative polymerization and fouling [5]. However, many oils have natural antioxidants which aid in extending biodiesel life. Overall, the beneficial composition of oils and fats are establishing biofuels as a dependable diesel extender or substitute.

The soaring growth of biodiesels raises the importance of integrating the fuel into pipeline distribution systems for transportation. ASTM had wishful desires to incorporate B5 (5% biodiesel, 95% petroleum diesel) as a fuel alternative in gas turbines due to its high production levels and respectable quality. Rod Lawrence, a quality control manager at Magellan Midstream Partners L.P., stated that 2 billion gallons of 5 percent biodiesel blend produces about 40 billion gallons of fuel products every year [6]. This significant quantity of fuel plays a palpable role in U.S. petroleum industries relieving high marketing demands. ASTM also added S15 grade, a light, middle distillate fuel requiring a maximum of 15 ppm sulfur, as an “Ultra-Low Sulfur” specification grade to gas turbine fuels in order to differentiate from S500, which was assigned to the “Low Sulfur” grade [7]. The U.S. Environmental Protection Agency, EPA, had stringent diesel emission standards that place emphasis on sulfur content. For example, the 500-ppm sulfur highway limit was established in 1993 and drastically changed in 2006 to 15 ppm [8].

In a National Renewable Energy Laboratory (NREL) study, B20 is subjected to accelerated aging to quadruple the process of fuel oxidation and other degradative reactions, and to mimic the conditions of standard long-term storage. B20 was re-additized to extend the life of the fuel and allow it to continue aging. Re-additization is the process where additives are incorporated into petroleum to ensure the lubricant meets the correct specifications for each instrument. Oxidative degradation of biodiesel results from the presence of unsaturated components such as polyunsaturated fatty acid esters which classifies the fuel as biodegradable [9]. The oxidation mechanism of polyunsaturated fatty acid esters consists of three main phases. Phase 1 is the induction period (IP) where oxygen is slowly consumed [9]. The fuel’s lifespan is dependent on oxygen availability and antioxidant concentrations, both of which gradually decrease in this phase [9]. Phase 2 is the exponential phase where oxygen is rapidly consumed, and peroxides form hastily [9]. Phase 3 begins the final degradation of the fuel where the rate of peroxide consumption is greater than the rate of formation [9]. Unsaturated components in biodiesel have a significant impact on the fuel’s stability and proper function. While biodiesel has a higher oxygen content compared to petroleum diesel, it also is more prone to oxidize which raises concern for the fuel’s storage life [10]. Moderating both the benefits and detriments of biodiesels are important in determining the optimal blend percentages. Re-additization is a salient solution to this problem by reducing oxygen consumption, thus improving the fuel’s storage life.

ASTM D4625 Standard Test Method for Middle Distillate Fuel Storage Stability at 43 °C (110 °F) achieved consistent results for a handful of B20 field samples before re-additization. All B20s with oxidative reserve values over six hours remained within the acid value specification of 0.3 mg KOH/g and above a three-hour oxidative reserve after 12 weeks under D4625 conditions. However, just five out of eight of the B20s with the highest oxidative reserve remained above six-hour oxidative reserve after 36 weeks under the same conditions. After re-additization, all eight samples but one reached TAN > 0.3 mg KOH/g at IP < 0.5 hour. The results are displayed in Table 1, where weeks are denoted as months of storage time under ASTM D4625 conditions.

Table 1. Samples after re-additization [11]

Notable points of discussion from Table 1 include comparing Sample A with the lowest initial IP and Sample C with the highest initial IP.

Figure 1. Sample A TAN [11]

p>The TAN graphs for Sample A and C are shown in Figures 1 and 2 respectively.

Figure 2. Sample C TAN [11]

Figures 1 and 2 show that base B20 for Sample A has a storage time of 4 months while Sample C has a storage time of 36 months. Both samples exceeded TAN specification quickly denoting rapid degradation after allotted storage time without re-additization. However, with re-additization at < 4hr and < 2hr, storage time increased dramatically for both samples. For further tests, Sample B had three re-additizations performed as shown in Figure 3.

Figure 3. Sample B TAN [11]

According to Figure 3, Sample B had an average storage time of 30 months and a re-additization at <4 of 48 months. However, re-additization at < 0.5 hr went rapidly out of spec for TAN which indicated that re-additization at low IP may not provide benefits as expected. The rapid degradation of Sample B conceivably resulted from insoluble formations such as unsaturated materials. Insoluble formations with respect to TAN is shown in Figure 4.

Figure 4. Insoluble formation vs TAN [11]

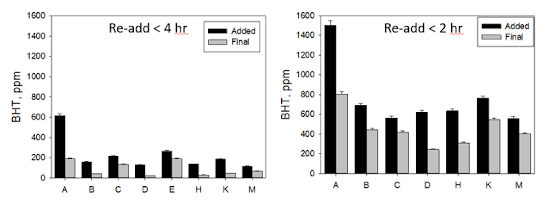

Figure 4 shows that there is no clear correlation between TAN and total insoluble formations. TAN > 0.3 does not guarantee insolubles and TAN < 0.3 does not have substantial insolubles to be conclusive. Therefore, antioxidant concentrations were measured to determine the correlation with fuel life. Figure 5 shows that BHT had significantly different results for re-additization at < 4 hours and < 2 hours. Re-additization at < 4 hours required approximately four times the amount of BHT to reach 6 hour IP compared to re-additization at< 2 hours.

Figure 5. Antioxidant concentrations[11]

While biofuels already have natural antioxidants that improves storage life for biodiesels, re-additization significantly extends the life even further. However, there are positive and negative effects of biodiesel in petroleum blends. Amidst the hindrances, the ceiling for biofuel is high and it is plausible for the fuel to be a dependable alternative to petroleum diesel.

Works Cited

[1] (2015, February 20). Retrieved from https://www.greenaironline.com/news.php?viewStory=2048

[2] (2015. February 2). Revised ASTM standard expands trace FAME limit in jet fuels @BiodieselMag. Retrieved from http://www.biodieselmagazine.com/articles/295372/revised-astm-standard-expands-trace-fame-limit-in-jet-fuels

[3] (n.d.). Biodiesel Production and Distribution. Retrieved from https://afdc.energy.gov/fuels/biodiesel_production.html

[4] (2018, June 11). U.S. Energy Information Administration - EIA - Independent Statistics and Analysis. Retrieved from https://www.eia.gov/energyexplained/biofuels/biodiesel.php

[5] (2019, April 3). Farm-Energy. (2019, April 12). Animal Fats for Biodiesel Production. Retrieved from https://farm-energy.extension.org/animal-fats-for-biodiesel-production/

[6] (2017, January 23). Technical work lays foundation for biodiesel market growth @BiodieselMag. Retrieved from http://www.biodieselmagazine.com/articles/2144266/technical-work-lays-foundation-for-biodiesel-market-growth

[7] (2014, March 3). ASTM revises D975 specification for diesel fuel oils; new designation for sulfur content. Retrieved fromhttps://www.greencarcongress.com/2014/03/20140303-astm.html

[8] (2009, December). United States: Diesel Fuel. Retrieved from https://www.dieselnet.com/standards/us/fuel.php

[9] (2014, August 15). Long-term storage stability of biodiesel and biodiesel blends. Retrieved from https://www.sciencedirect.com/science/article/pii/S0378382014003361

[10] Ciolkosz, D. (2019, September 24). What's So Different about Biodiesel Fuel? Retrieved from https://extension.psu.edu/whats-so-different-about-biodiesel-fuel.

[11]Christensen, Alleman, Teresa, McCormick, & L., R. (2018, April 25). Re-additization of commercial biodiesel blends during long-term storage. Retrieved from https://www.osti.gov/servlets/purl/1461852.

Dr. Raj Shah is an elected fellow of RSC, AIC, STLE, NLGI, InstMC, and El. He is Chartered Petroleum Engineer from the Energy Institute, a certified Chemical Engineer from the National Certification Commission in Chemistry and Chemical Engineering and a Chartered scientist from the science council. Currently, he is a Director at Koehler Instrument Company located in Long Island, NY where he has been for 25 years.

Mr. Anson Law is currently part of the thriving internship at Koehler Instrument Company and is a senior who is working towards a master’s degree in chemical engineering at Stony Brook University.

Mr. David Forester has over 40 years experience in the petroleum industry focusing on fuels and is an active member of the ASTM Biodiesel committee.