Microscopic plastic with a size of several μm to 5 mm or less is called microplastic. As a marine environmental problem that adversely affects coastlines and marine ecosystems, and consequently may potentially affect human health, microplastics have become a global issue in recent years. Because action is necessary to protect the global environment, various analytical devices are used to designate the sources of microplastics and study countermeasures.

Microplastics are classified into two types, primary microplastics and secondary microplastics. Primary microplastics refers to substances that are used as raw materials in industrial abrasives, scrubbing agents, and the like. Polyethylene (PE) and polypropylene (PP) are frequently used in these applications. Secondary microplastics are substances that are generated when large plastic products are reduced to a fine size of 5 mm or less by external factors, such as ultraviolet radiation, and include various types of plastics.

The Fourier transform infrared (FTIR) spectrophotometer is generally used in qualitative analysis of plastics and is already utilized in surveys of the actual condition of discharges into rivers. However, because many actual microplastics are degraded in the environment, mainly by ultraviolet radiation, there may be no matches in analyses using a standard FTIR library.

This article introduces measurement of microplastics with a size on the order of several mm and use of the Shimadzu thermal-damaged plastics library to identify the samples.

Instrumentation and Measurement Sample

For this analysis, we used Shimadzu’s IRSpirit™ FTIR spectrophotometer with a Shimadzu QATR™-S ATR measurement accessory integrated with the sample compartment in the unit. The measurement sample consisted of microplastics collected at a seacoast in various shapes, including spherical and pellet-like, in different colors (Figure 1).

Figure 1. Microplastics Collected at Seacoast

Measurement Method

We used the attenuated total reflectance (ATR) method with the FTIR. An absorption spectrum of a sample surface can be obtained by placing the sample on the ATR prism and measuring the total light reflected by the sample surface. The light penetration depth in ATR is several μm. Figure 2 shows the condition of measurement.

Figure 2. Condition of ATR Measurement

Thermal-Damaged Plastics Library

The Shimadzu thermal-damaged plastics library is a library containing spectral data for 13 types of plastic in an unheated condition and when heated to various temperatures from 200 °C to 400 °C.

Degradation of plastics begins from the formation of carbon-centered radicals as a result of the dissociation of hydrogen from carbon-hydrogen bonds caused by the energy of heat or light. When oxygen reacts with the radicals, the formation of additional radicals and dissociation of hydrogen occur in a kind of chain reaction, and inert substances are also formed by bonding between pairs of radicals. Plastics are degraded by this process, which is accompanied by molecule scission and crosslinking (1).

Although large differences in the progress of degradation can be seen in ultraviolet degradation and thermal degradation, the factors that govern the progress of degradation are essentially the same (2). Since the changes that occur in the infrared spectrum are often similar, the thermal-damaged plastics library can also be used in qualitative analysis of ultraviolet-degraded microplastics in many cases.

Figure 3 shows the infrared spectra of acrylonitrile butadiene styrene (ABS) resin when irradiated with ultraviolet light, and Figure 4 shows the infrared spectra of ABS resin when subjected to heating. In the case of ABS, peaks associated with stretching vibration of the OH radical and C=O radical appear under both ultraviolet and thermal conditions, showing that oxidative degradation occurs due to exposure to ultraviolet radiation and heat.

Figure 3. Infrared Spectra of ABS Resin (Ultraviolet Irradiation)

Figure 4. Infrared Spectra of ABS Resin (Heating)

Measurement Results

Among the microplastics collected at the seacoast, those with sizes of 5 mm or less were measured. Table 1 shows the measurement conditions. Figure 5 and Figure 6 show images of the samples and the measurement results for two samples.

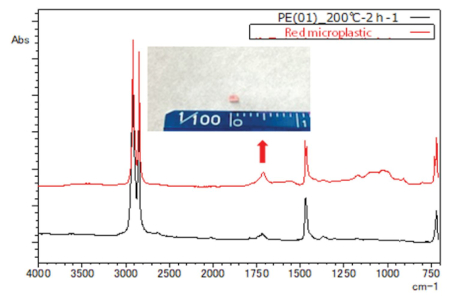

From the results in Figure 5, a hit for polypropylene (PP) heated at 200 °C for 4 h was obtained from the thermal-damaged plastics library for the white microplastic. From Figure 6, a hit for polyethylene (PE) heated at 200 °C for 2 h was obtained for the red microplastic. It can be inferred that both microplastics were degraded by oxidative degradation caused by ultraviolet radiation.

Figure 5. Measurement Result and Library Search Result for White Microplastic

Figure 6. Measurement Result and Library Search Result for Red Microplastic

Conclusion

Microplastics collected at a seacoast were measured by FTIR spectroscopy. Simple and easy measurement was possible using the ATR method. Quick qualitative analysis of degraded microplastics was also possible using the Shimadzu thermal-damaged plastics library.

In cases where qualitative analysis by a more certain method is desired, we recommend measuring plastic that has been intentionally degraded by ultraviolet irradiation and comparing that sample with the actual sample.

Risa Fuji works in the Global Applications Department at Shimadzu.

References

1. Yamanoi, H. The Mechanisms of Polymer Degradation Discoloration and Stabilization, Journal of the Materials Life Society, Japan, 2007, 19(3), 103-108.

2. Oki, Y. Degradation of Plastic Materials, Journal of the Metal Finishing Society of Japan, 1973, 24(4), 229-238.