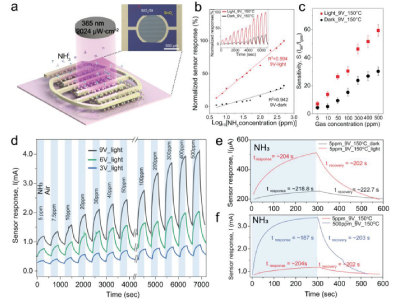

The schematic structure of the NH3 gas sensor utilizing large area SnO2 film. Credit: Chung Kim Nguyen et al.

A collaborative team of researchers has developed a novel sensor to detect the presence of harmful ammonia gas. Exposure to ammonia is known to cause chronic lung conditions as well as organ damage in humans, with a recent increase in worldwide ammonia production exposure events are likely to become more common.

The research, published in Advanced Functional Materials, outlines the development of the sensor proof of concept. Constructed of atomically thin transparent tin dioxide, the sensor is capable of detecting ammonia at much lower concentrations than similar sensors. To detect finite levels of ammonia, the sensor relies on changes in the conductivity of the tin oxide film caused by the presence of ammonia in the air.

To test the sensitivity of the sensor, researchers exposed it to ammonia concentrations ranging from 5-500 ppm under different environmental conditions. Using the same chamber, the researchers also analyzed the sensor's selectivity to non-target gasses such as carbon dioxide. Analysis revealed that the sensor offered excellent selectivity while improving the sensitivity when compared to current technologies.

The researchers believe that the novel sensor developed offers a less cumbersome and safer approach to ammonia detection than current devices.

"Current approaches to ammonia detection produce accurate measurements but require expensive laboratory equipment with qualified technicians, extensive sampling and preparation," said Dr. Chung K. Nguyen. "This process is often time-consuming and not portable, due to the size of the equipment needed. In addition, the manufacturing of today's ammonia detectors involves expensive and complicated processes to prepare sensitive layers for sensor fabrication."

To further develop and prototype the technology, the team intends to collaborate with industry partners adding that, "The fabrication method aligns well with existing silicon industry manufacturing processes, making it suitable for mass production."