Featured Article

Despite advances in stationary phase chemistry, liquid chromatography instrumentation and particle miniaturization, the development of a portable LC system has remained elusive because of the difficulty of downscaling hardware and reducing solvent consumption.

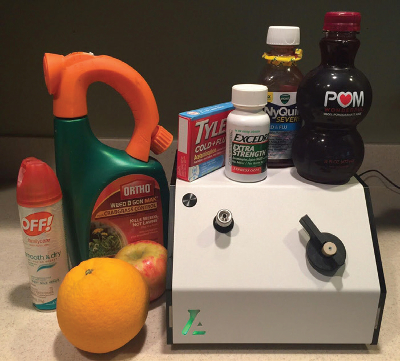

The compact, standalone Alltesta HPLC-based analyzer (Figure 1) (SIELC Technologies, Wheeling, Ill.) overcomes these limitations and offers the following features:

Figure 1 – Alltesta Mini HPLC analyzer.

Figure 1 – Alltesta Mini HPLC analyzer.- Provides preliminary testing for further downstream analysis

- Assesses hazardous compounds that are difficult or dangerous to transport

- Handles sensitive samples such as those collected from a crime scene

- Performs testing in emergency situations, such as biowarfare and catastrophic environmental pollution events

- Analyzes unstable radioactive compounds that have a short half-life

- Analyzes pharmaceuticals and nutraceuticals.

System features

Field technicians may not be experienced analytical chemists. The Alltesta analyzer includes over 1000 HPLC methods preset for a diverse array of compounds, which eliminates the need for expertise in method development. Preset methods may be customized by end users for specific applications and for use in quality control. Lifetime free method-development screening (vetting of methods developed by users) is included, as is a continually growing library of methods from SIELC.

A 12” touchscreen tablet is the only external hardware required for operation. This interface eliminates the need for a computer, monitor, keyboard and other bulky accessories while facilitating easy operation in the field or laboratory; wireless connectivity allows user mobility during analysis.

The Alltesta pump precisely delivers fluid at flow rates from 0.10 mL/min to 4.0 mL/min using up to 5000 psi (350 bar) of continuous pressure. Pulsation is reduced by a built-in dampener that contains minimal dead volume and is free of dampener fluid. A two-channel degasser removes dissolved air from the pumping liquid, increasing accuracy and performance.

The system shuts down operation when a specified pressure or time is reached. A two-channel proportional valve enables selection of two different solvents in any ratio from 0 to 100% in 1% increments, which allows running gradient and isocratic methods. In the most common configuration, the built-in autosampler accepts 40 standard vials; a 96-well-plate format is optionally available.

Using only a three-wire connection, the RS485/CAN interface permits control of multiple devices. Additional features include adjustable needle depth and an optional patented wash system that minimizes sample cross-contamination.

An LED-based detector delivers a narrow, intense bandwidth; the long-lasting, low-noise light source provides high sensitivity. Its small internal flow path volume minimizes band spreading, and only very chemically stable materials, i.e., PEEK, PTFE and quartz, contact the fluid.

Applications

Analysis of pesticides and contaminants

Drug residues commonly contaminate agricultural products,1 and may enter through a variety of means, such as being present in water during the irrigation process. The Alltesta analyzer was used to identify several contaminants in black and green tea products (Figure 2). Atorvastatin, a common cholesterol medication, and two fungicides—picoxystrobin and pyrimethanil—were separated from native tea compounds and from each other by more than 1 minute. Analysis was performed after merely extracting tea products in water, which attests to the minimal sample preparation required. This enables onsite analysis at a tea production facility to rapidly identify contaminants such as medications and agricultural product residues. In this case, tea samples were spiked, but this analysis represents the ability of the analyzer to separate nonnative tea compounds from contaminants, such as agricultural and pharmaceutical products.

Figure 2 – Separation of contaminants in tea with no sample preparation: 1) atorvastatin, 2) picoxystrobin, 3) pyrimethanil. Column: Primesep 200, 4.6 × 150 mm; mobile phase: 50% MeCN, 0.05% H3PO4; flow rate: 1.0 mL/min; detection: 270 nm; sample preparation: none (direct injection of tea extracts after spiking of samples).

Figure 2 – Separation of contaminants in tea with no sample preparation: 1) atorvastatin, 2) picoxystrobin, 3) pyrimethanil. Column: Primesep 200, 4.6 × 150 mm; mobile phase: 50% MeCN, 0.05% H3PO4; flow rate: 1.0 mL/min; detection: 270 nm; sample preparation: none (direct injection of tea extracts after spiking of samples).In another application, the analyzer was used to achieve high-resolution separation of a complex mixture of seven pesticides (Figure 3), simulating analysis that can be performed onsite at a quality control facility in the agriculture industry. Peaks were well separated and distributed uniformly along 8 minutes of analysis time and using less than 2 mL of acetonitrile. Despite the structural similarities of some of the analytes, i.e., 4-chlorophenoxyacetic acid and 2,4-dichlorophenoxyacetic acid, in particular, the analyzer was able to achieve 4 minutes of separation between these compounds using the Primesep D reversed-phase column (SIELC Technologies).

Figure 3 – High-resolution separation of seven pesticides in a mixture: 1) dichloran, 2) folpet, 3) azinphos-ethyl, 4) 4-chloro-phenoxyacetic acid, 5) mecoprop, 6) triclopyr, 7) 2,4-dichlorophenoxyacetic acid. Column: Primesep D, 3.2 × 50 mm; mobile phase: 35% MeCN, 0.30% H3PO4; flow rate: 0.6 mL/min; detection: 270 nm; sample preparation: 1 mg/mL in 1:1 MeCN:water.

Figure 3 – High-resolution separation of seven pesticides in a mixture: 1) dichloran, 2) folpet, 3) azinphos-ethyl, 4) 4-chloro-phenoxyacetic acid, 5) mecoprop, 6) triclopyr, 7) 2,4-dichlorophenoxyacetic acid. Column: Primesep D, 3.2 × 50 mm; mobile phase: 35% MeCN, 0.30% H3PO4; flow rate: 0.6 mL/min; detection: 270 nm; sample preparation: 1 mg/mL in 1:1 MeCN:water.Analysis of food dyes in consumer products

The Alltesta analyzer provides rapid (<3 minute) analysis of food dyes commonly used in products in the beverage and pharmaceutical industries. Allura Red (Red #40) was quantified in both soft drinks (Figure 4a) and over-the-counter drugs (Figure 4b) using the analyzer equipped with an Obelisc N mixed-mode column (SIELC Technologies). Minor differences in Allura Red AC concentration were detected in the samples tested. Ammonium formate was employed in a low-concentration gradient in both cases to ensure fast separation and LC/MS compatibility.

Figure 4 – a) Relative abundance of Allura Red AC in soft drinks: 1) Powerade Zero fruit punch (The Coca-Cola Company, Atlanta, Ga.), 2) Nice! black raspberry (Walgreens, Deerfield, Ill.), 3) Sparkling Ice Cherry Limeade, 4) Sparkling Ice Pink Grapefruit (Sparkling Ice, Preston, Wash.), 5) Mountain Dew Live Wire (Pepsico, Purchase, N.Y.). Column: Obelisc N, 3.2 × 50 mm; mobile phase: MeCN 50%, AmFm pH 3.0 70 mmol; flow rate: 0.6 mL/min; detection: 525 nm; sample preparation: 1 mg/mL in 1:1 MeCN:water. b) Relative abundance of Allura Red AC in over-the-counter drugs: 1) Walgreens Nighttime Cough Relief, 2) Robitussin Cough & Cold (Pfizer, New York, N.Y.), 3) Mucinex Children’s Multi-Symptom Cold (Reckitt Benckiser, Parsippany, N.J.), 4) Robitussin Cough & Chest, 5) Children’s Mucinex Multi-Symptom Cold Nighttime. Column: Obelisc N, 3.2 × 50 mm; mobile phase: MeCN 50%, AmFmpH 3.0 70 mmol; flow rate: 0.6 mL/min; injection: 100 μL; detection: 525 nm; sample preparation: 1 mg/mL in 1:1 MeCN:water.

Figure 4 – a) Relative abundance of Allura Red AC in soft drinks: 1) Powerade Zero fruit punch (The Coca-Cola Company, Atlanta, Ga.), 2) Nice! black raspberry (Walgreens, Deerfield, Ill.), 3) Sparkling Ice Cherry Limeade, 4) Sparkling Ice Pink Grapefruit (Sparkling Ice, Preston, Wash.), 5) Mountain Dew Live Wire (Pepsico, Purchase, N.Y.). Column: Obelisc N, 3.2 × 50 mm; mobile phase: MeCN 50%, AmFm pH 3.0 70 mmol; flow rate: 0.6 mL/min; detection: 525 nm; sample preparation: 1 mg/mL in 1:1 MeCN:water. b) Relative abundance of Allura Red AC in over-the-counter drugs: 1) Walgreens Nighttime Cough Relief, 2) Robitussin Cough & Cold (Pfizer, New York, N.Y.), 3) Mucinex Children’s Multi-Symptom Cold (Reckitt Benckiser, Parsippany, N.J.), 4) Robitussin Cough & Chest, 5) Children’s Mucinex Multi-Symptom Cold Nighttime. Column: Obelisc N, 3.2 × 50 mm; mobile phase: MeCN 50%, AmFmpH 3.0 70 mmol; flow rate: 0.6 mL/min; injection: 100 μL; detection: 525 nm; sample preparation: 1 mg/mL in 1:1 MeCN:water.Analysis of prescription and over-the-counter (OTC) drugs

Separation of prescription antibiotics is shown in Figure 5. As with the analysis of pesticides in Figure 3, some of the analytes, namely sulfaguanidine and sulfanilamide, resemble each other structurally, yet separation was done in 15 minutes using the Obelisc R reversed-phase column. The application is LC/MS-compatible, and the low level of formic acid enhances ionization.2 As described, the method also preserves analytical sensitivity.

Figure 5 – Separation of a complex mixture of nine antibiotics: 1) sulfanilamide, 2) sulfaguanidine, 3) sulfadiazine, 4) norfloxacin, 5) tylosin, 6) josamycin, 7) dapsone, 8) sulfaquinoxaline, 9) flumequine. Column: Obelisc R, 4.6 × 150 mm; mobile phase: MeCN 0–25% in 6 min, then 70% for 14 min; formic acid 0.05–0.3% in 6 min, 14 min hold; flow rate: 1.0 mL/ min; detection: 270 nm; sample preparation: 1 mg/mL in 1:1 MeCN:water.

Figure 5 – Separation of a complex mixture of nine antibiotics: 1) sulfanilamide, 2) sulfaguanidine, 3) sulfadiazine, 4) norfloxacin, 5) tylosin, 6) josamycin, 7) dapsone, 8) sulfaquinoxaline, 9) flumequine. Column: Obelisc R, 4.6 × 150 mm; mobile phase: MeCN 0–25% in 6 min, then 70% for 14 min; formic acid 0.05–0.3% in 6 min, 14 min hold; flow rate: 1.0 mL/ min; detection: 270 nm; sample preparation: 1 mg/mL in 1:1 MeCN:water.Within 8 minutes, the analyzer separated the active ingredients in common OTC medications (Figure 6). Despite the presence of excipients that lead to prominent yet unidentified peaks, a standard Primesep 200 reversed-phase column was used to separate the major constituents of these drugs.

Figure 6 – a) Separation of the active ingredients in Tylenol Severe Allergy Maximum Strength Nighttime: 1) acetaminophen, 2) pseudoephedrine; 3) diphenhydramine. Column: Primesep 200, 3.2 × 100 mm; mobile phase: MeCN 5–50% in 5 min with 4-min hold, H2SO4 0.03–0.2% in 5 min with 4-min hold; flow rate: 0.6 mL/min; detection: 270 nm; sample preparation: 1 mg/mL in 1:1 MeCN:water. b) High-resolution separation of the active ingredients in Children’s Mucinex Multi-Symptom Cold Nighttime: 1) acetaminophen, 2) phenylephrine, 3) diphenhydramine. Column: Primesep 200, 3.2 × 100 mm; mobile phase: MeCN 5–50% in 5 min with 4-min hold, H3PO4 0.05–0.3% in 5 min with 4-min hold; flow rate: 0.6 mL/ min; detection: 270 nm; sample preparation: 1 mg/mL in 1:1 MeCN:water.

Figure 6 – a) Separation of the active ingredients in Tylenol Severe Allergy Maximum Strength Nighttime: 1) acetaminophen, 2) pseudoephedrine; 3) diphenhydramine. Column: Primesep 200, 3.2 × 100 mm; mobile phase: MeCN 5–50% in 5 min with 4-min hold, H2SO4 0.03–0.2% in 5 min with 4-min hold; flow rate: 0.6 mL/min; detection: 270 nm; sample preparation: 1 mg/mL in 1:1 MeCN:water. b) High-resolution separation of the active ingredients in Children’s Mucinex Multi-Symptom Cold Nighttime: 1) acetaminophen, 2) phenylephrine, 3) diphenhydramine. Column: Primesep 200, 3.2 × 100 mm; mobile phase: MeCN 5–50% in 5 min with 4-min hold, H3PO4 0.05–0.3% in 5 min with 4-min hold; flow rate: 0.6 mL/ min; detection: 270 nm; sample preparation: 1 mg/mL in 1:1 MeCN:water.Miniature analyzer

SIELC also offers an Alltesta Mini for applications that are even more sizesensitive. In contrast to the full-sized analyzer, which measures 8” × 13” × 7” and weighs 22 lb, the 6-lb Mini is 8” × 8.5” × 9”. Offering the same technology and method-development library as the larger version, Alltesta Mini is suited for the following applications:

- In-home water supply testing

- Onsite assessment of chemically contaminated areas

- Field analysis involving situations in which samples must be transported repeatedly to and from a laboratory for analysis in the absence of an onsite testing device such as the analyzer, or samples that require refrigeration, insulation, etc., and complicate the transportation process due to the added bulkiness of these materials

- In-process monitoring of production in pharmaceutical and chemical manufacturing facilities

- Teaching the fundamentals of chromatography to college students using a hands-on approach to provide real-world experience in method development and HPLC analysis.

Future directions

Currently under development is a universal platform for the screening of drugs, metabolites, contaminants and other compounds. A priority will be to minimize the number of columns and mobile phase combinations.

References

- Drug residues and microbial contamination in food: monitoring and enforcement. In The Use of Drugs in Food Animals: Benefits and Risks. Washington, D.C.: The National Academies Press, 1999.

- www.waters.com/waters/en_US/Solvents-and-Caveats-for-LC-MS/nav.htm?cid=10091173&locale=en_US

The authors are with SIELC Technologies, 804 Seton Ct., Wheeling, Ill. 60090, U.S.A.; tel.: 847-229-2629; e-mail: [email protected]; www.sielc.com. The authors would like to acknowledge all scientists and engineers at SIELC.