This article was developed by American Laboratory editors from an original presentation by the author. See https://goo.gl/6GJQkC

Static charge is a function of friction from motion (for example, stockinged-feet sliding on a carpet) or contact and separation (think of a roll of adhesive tape that curls up on itself as it is unspooled). Once static charge is produced, an electrostatic field is generated, which has a force component.

Contact and separation, or triboelectric charging, occurs when two dissimilar materials are put in contact with each other and are then separated. Any material can be charged triboelectrically; whether or not it remains charged depends on whether it is a conductor or an insulator.

Many of the materials used in clean measurement areas are excellent insulators that can create and hold very high levels of static charge for long periods of time. Human hands, water and aluminum are examples of positively charged materials; polypropylene, silicon and PTFE are materials that are more negatively charged.

Factors that affect triboelectric charging are:

- Condition of the two surfaces (rough surface = less charge)

- Size of the areas being rubbed/separated (smaller area = less charge)

- Pressure applied to the surfaces of the two materials before separation (low pressure = lower charge)

- Speed of separation (slow = less charge)

- Humidity (high = less charge).

Conductors have the ability to drain charge, but they have to come in contact with a larger object that can accept the charge or send the charge to ground. If the conductor is isolated from ground, it will hold a charge. In precision weighing, the balance pan, made of stainless steel, is isolated from ground and will hold a static charge. This can cause issues with weighing accuracy.

Effects of static charge on precision weighing

Static charges have both a field component and a force component. The field component will attract or repulse particulates. A strong charge on filter paper will attract particulates. Electrostatic force can cause movement in small objects, including the weigh pan of an analytical balance. Static charge attracts particles to weighing samples, transport carriers and scale components. Weighing inaccuracy, sample loss and contamination result. A static charge on samples and other objects in the weighing chamber interacts with the components of the scale, resulting in inaccuracies and “zero” drift.

Methods of static control

Various strategies can be employed to control static. Steps that should be implemented include: grounding both work area and personnel; control of insulating and dispersive materials; ionization to remove the static charge from insulators; and grounding anything conductive, most importantly, equipment operators.

People are conductive and often wear insulating shoes. Thus, charges that develop on lab technicians—the dryer the environment, the greater the buildup—will induce a static charge as soon as contact is made with samples, weigh boats, spatulas and other tools and with the weighing chamber itself.

Figure 1 – Anti-static wrist straps drain charges from workers into a grounded system.

Figure 1 – Anti-static wrist straps drain charges from workers into a grounded system.Antistatic wrist straps will drain any static charge off into a grounded system and keep technicians static-free, but are best when working in one place for a fixed period of time (see Figure 1). Carbon or metal particles can be added to sample containers, weigh boats and other sample handling tools to help dissipate the build-up of static charge.

While lab technicians can be grounded through the use of a wrist strap, the garments they wear can defeat this strategy if they are made of insulative, synthetic materials. Therefore, garments made of natural materials will help with static control.

Air ionization

Air ionizers create positively and negatively charged air molecules. Charged objects in the work area will attract the oppositely charged air molecule, thereby neutralizing the static charge on the target object.

Ionization types

Alpha, or nuclear, ionizer

Nuclear, or alpha, ionizers use a radioactive material, Polonium-210, to ionize air in the immediate vicinity. Alpha ionizers emit safe helium nuclei that impact with the surrounding air molecules to dislodge electrons. This process always produces equal numbers of both positive and negative air ions, which is necessary for complete static neutralization. The alpha sources are safely sealed within the static control device. Alpha ionizers require no power to operate. The air ions that are created are attracted to the object with the static charge, which is then neutralized. Alpha ionizers do have an “effective” life of 12 to 18 months depending on the application. Some states have regulations about how Polonium-210 is used and disposed of.

Corona discharge ionizer

Corona discharge ionizers use a power supply to provide a high voltage, typically in excess of 5000 volts, which creates a strong energy field that strips electrons from the surrounding air. Both AC and DC style corona ionizers are equally effective at neutralizing static charge.

The emitter points should be recessed to eliminate the chance of puncture and snagging. A shielded power cable is recommended to eliminate the potential for electrical noise that can interfere with the sensitive electronics in the balance. Most manufacturers offer “shockless” electrical ionizers for added safety.

Piezoelectric ionizer

These devices employ mechanical force on crystals to generate voltage. A handle is squeezed and released to generate both positive and negative air ions. However, due to the inherent imbalance in this type of device, the benefits of its use are minimal at best, and they always tend to charge samples negatively. For this reason, piezoelectric ionizers are not recommended for this application.

Static charge generation is unavoidable and causes inaccuracies and movement of materials, even weigh pans. Use of the appropriate static control device for a specific situation should remove the static and the resulting problems.

Static control in practice

As an example, let’s look at specimens on a filter paper that needs to be precisely weighed. A static charge on the filter paper can attract airborne contaminants and induce a charge on the weigh pan, both of which can create errors in measurement. The solution would be to remove static charge, which can be done outside or within the weigh chamber.

Some static control devices will neutralize both sides of the paper, while others neutralize just one side. In the latter case, the filter paper should be turned over to neutralize both sides. (Videos showing these devices in use can be found at http://nrdprecisionweigh.com/products/BF1_vid.html and http://nrdprecisionweigh.com/products/BF2_vid.html).

Static charges on weigh boats, papers, vials and other sample holders can induce charges in the specimen and on the sample holder itself, and the charge can be on the interior and exterior of the holder.

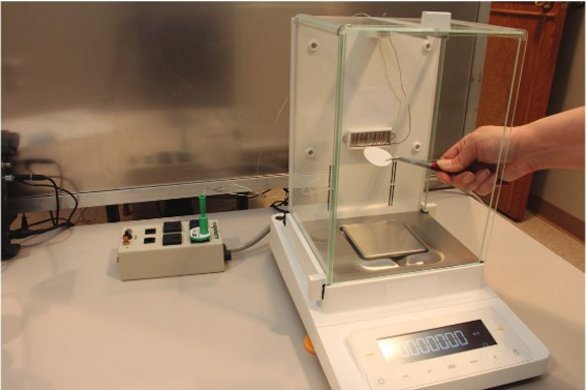

Figure 2 – The in-chamber grounding package includes an ionizing cartridge and mounting bracket.

Figure 2 – The in-chamber grounding package includes an ionizing cartridge and mounting bracket.

As an option, an ionizing blower can be used to quickly and efficiently remove all of the surface charges on both the inside and outside of objects. An ionizing cartridge is mounted inside a small benchtop fan that creates a stream of air that removes static from the surfaces of irregularly shaped objects. This can be used to remove the charge from a person wearing synthetic garments. The fans in some units run for a short time and then shut off so that they are only blowing when needed. The fan can also be picked up and used to ionize the inside and outside of the weigh chamber. An in-chamber package consisting of the ionizing cartridge, mounting bracket and grounding kit is shown in Figure 2.

A single-bar, electrical AC ionizer generates a very large ion cloud to accommodate objects of various sizes. Because no air is required to move the ions away from the device, it is an ideal solution for removing static from powders and filter papers, and can also be used with weigh boats and plastic spatulas. Static charge is easily removed by passing items in front of the ionizer before placing them in the weigh chamber. It’s important to note that a charge can pass to the outside of a container simply by handling it; therefore, vessels should be rotated completely in the ion cloud. If the vessel has no top, it should be held facing the bar so that the inside is discharged as well. (A video of the bar ionizer in use can be viewed at www.nrdprecisionweigh.com/products/6105.html)

Effects of static on weighing

Users will often notice the numbers changing on the scale display when a weigh boat is placed on the weigh pan. If the pan is being pulled up while trying to tare the balance, it will be difficult to get back to zero to offset the effects of the static charge on the pan. Depending on the amount of humidity in the air, drift in the “zero” can be observed. In critical applications, medical dosing, for example, this behavior can easily lead to inaccurate amounts.

Figure 3 – Electrostatic dissipative workstations are recommended for areas that are used frequently.

Figure 3 – Electrostatic dissipative workstations are recommended for areas that are used frequently.Protecting personnel

When working with very precise measurements, it is critical to remove static from the lab technician. Static charge on clothing can easily be transferred to the specimens and the weigh chamber of the scale itself. Complete electrostatic dissipative (ESD) workstations (Figure 3) are recommended for all areas that see frequent and/or long-term use. The workstation includes an ESD mat on which the balance resides and the samples are placed. Any charges on the lab technician are transferred to the mat, including those from their garments and wrist straps with common point ground. All of these things are connected at the back of the mat which is, in turn, connected to the facility ground.

Greg Gumkowski is engineering and sales manager, NRD Advanced Static Control, 2937 Alt Blvd., P.O. Box 310, Grand Island, N.Y. 14072-0310, U.S.A.; tel.: 800-525-8076; www.nrdprecisionweigh.com. Greg has degrees in Materials Science and Engineering Metallurgy and is a member of the ESD Association and an iNARTE-certified ESD technician.